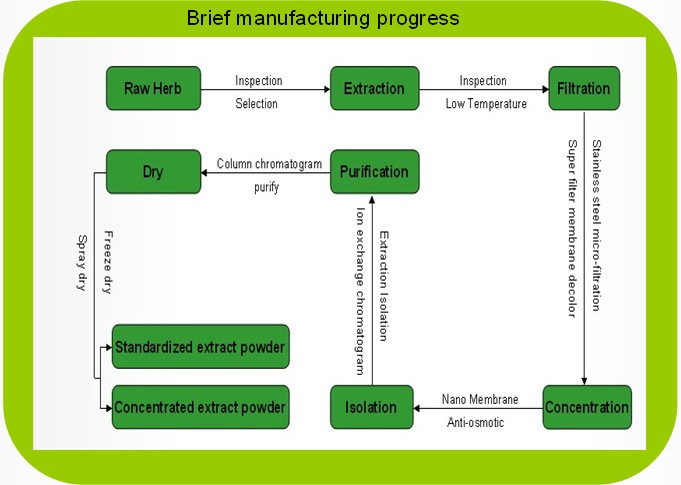

Plant extracts production technological process

1.Preparation: set processing methods, equipment and facilities, operation process and conditions, raw materials and requirements and quantity of accessories .

2.Extraction: set extraction method, operation process, extraction temperature, pressure, time and process conditions, the quantity of raw materials and solvent, equipment to be used, etc.

3.Solid-liquid separation:set separation methods and equipment, operation process, liquid concentration and separation temperature, equipment parameters, and other process conditions.

4.Concentration: set concentrated equipment, operation process, concentrated temperature, vacuum degree, time and other technology conditions, the number of materials and operating parameters.

5.Isolation: set the Isolation methods and equipment, operation process, the ph value, concentration, temperature, process conditions and material quantity and operating parameters.

6.Dry: set dry method, equipment and facilities, the operation process, the drying temperature, time and process conditions, the number of materials and its operating conditions.

7.Crushing and sieve analysis: set crushing and sieve analysis method, equipment, operation process, process conditions and material quantity and its operating conditions.

8.Packing: set packing methods, equipment, operation process, packaging specifications, process conditions and material quantity and its operating conditions.

10.Storage: set storage facilities, conditions, storage methods, storage time, etc.

Advanced technology applied in our manufacturing process:

1.Lower temperature through whole process to ensure function

2.Dynamic low temperature extraction, Nano-membrane isolation , Anti-osmotic concentration , Freeze dry.

3.High efficiency isolation to ensure high purification

4.Column adsorption chromatogram , Ion exchange chromatogram , adverse current Extraction

5.Advanced analysis instruments to ensure high quality HPLC, HPTLC, GC, UV, CE, etc.